Key Takeaways

- CNC milling machines use computerized controls to produce highly precise, complex parts from materials like metal and plastic, outperforming traditional manual machining methods.

- Key components include a sturdy machine frame, high-speed spindle with automatic tool changers, advanced control panels, and secure worktables with specialized fixtures.

- The process begins with CAD/CAM software converting digital designs into G-code, which guides multi-axis tool movements for step-by-step, repeatable material removal.

- CNC mills offer significant advantages: exceptional accuracy, high productivity, ability to machine complex shapes, reduced human error, material versatility, and enhanced worker safety.

- These machines are essential across industries such as aerospace, automotive, medical, electronics, and energy for producing both prototypes and high-volume production parts with tight tolerances.

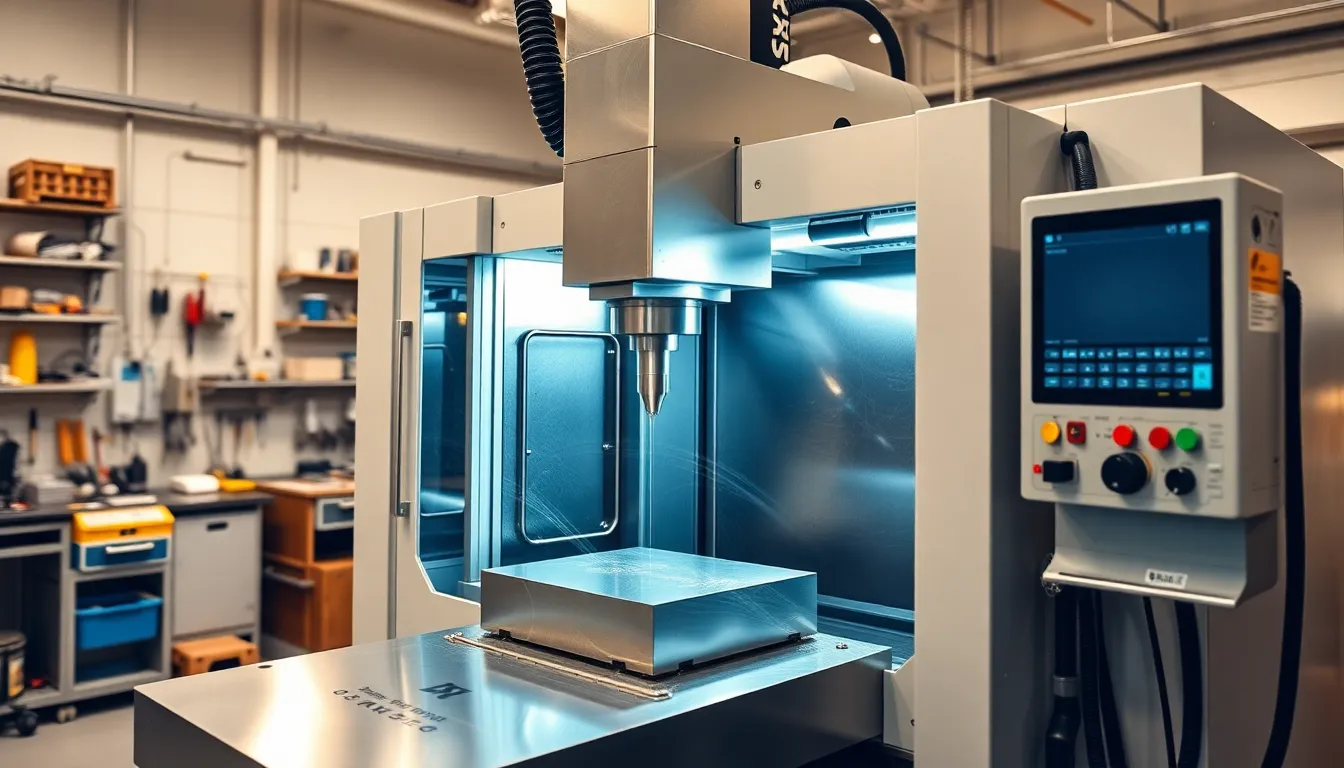

CNC milling machines use computerised controls to produce highly precise parts from materials like metal and plastic by following programmed instructions to move cutting tools along multiple axes. These automated systems convert digital designs into G-code instructions, enabling accurate material removal for complex geometries. CNC milling is essential across aerospace, automotive, medical, and electronics industries for both prototype development and high-volume production applications requiring tight tolerances.

What Is a CNC Milling Machine?

A CNC milling machine operates as a computer-controlled cutting system designed to produce precise parts from materials like aluminum, steel, and plastic. Computerized controls guide the machine’s multi-axis movements, allowing the spindle to cut, drill, or shape complex geometries with accuracy not possible using manual tools. Modern CNC milling machines in facilities like Yijin Hardware in Homestead, FL use advanced software to convert digital part designs into precise, repeatable toolpaths.

These machines handle tasks including slotting, contouring, drilling, and pocketing, which means they’re suitable for high-tolerance industries: aerospace, automotive, medical, and energy. Depending on the application, a CNC milling machine uses different cutting tools and fixtures to secure materials, quickly switching between operations with minimal manual intervention. With proper programming, these systems support both high-volume runs and one-off custom projects.

Yijin Hardware offers CNC milling with adjustable spindle speeds, multiple axis options, and compatible fixturing. Gavin Yi, CEO, leads the company’s focus on comprehensive precision manufacturing solutions, ensuring clients in Homestead and beyond receive finished components with tight dimensional tolerances and consistent repeatability.

Key Components of a CNC Milling Machine

A CNC milling machine operates with coordinated mechanical and electronic units. Each primary component carries out a specialized task for precise, repeatable, and accurate part production.

Machine Frame and Bed

The machine frame and bed form the structural foundation supporting all operational parts. Rigid frames constructed from cast iron or steel damping vibrations and ensuring precise machining, as seen in industrial models from Yijin Hardware in Homestead, FL. Heavy-duty beds maintain flatness and alignment through continuous use. Linear guideways and ball screws mount on the frame, facilitating smooth axis movement. Frames with reinforced welding or high-grade casting resist deformation during heavy milling or multi-axis operations.

Spindle and Cutting Tools

The spindle and cutting tools operate as the core of metal removal and shaping. Spindles rotate at up to 24,000 RPM in high-speed models, enabling accuracy for tasks like slotting and contouring of aluminum or medical-grade components. Yijin Hardware configures spindles for both high-torque and precision tasks, offering clients options for carbide, HSS, or coated inserts. Automatic tool changers (ATCs) store and switch tools mid-cycle, improving productivity. Spindle accuracy, runout, and thermal stability impact cut quality directly.

Control Panel and Computer System

The control panel and computer system execute digital designs by interpreting G-code and sending electrical signals to machine motors. At Yijin Hardware, advanced controllers integrate touchscreens and Windows-based software for fast program upload and real-time monitoring. Panels provide operators access to start, stop, override, and diagnostic data at any stage. Network interfaces enable remote diagnostics by engineers, linking Homestead, FL production with worldwide support. Safety interlocks and emergency stops are standard on all control panels.

Worktable and Fixtures

The worktable and fixtures anchor raw materials for precise processing. Rigid, T-slotted tables on Yijin Hardware’s systems support large or small aluminum, steel, or custom plastic blanks. Precision vises, pneumatic clamps, and custom modular fixtures keep parts still under cutting forces, improving dimensional accuracy. Fixtures are critical for repeatable jobs in aerospace and medical sectors, limiting vibration and reducing scrap. Table travel distance and weight capacity align with each mill’s axis range and spindle power.

How Does a CNC Milling Machine Work?

CNC milling machines use computer controls and precision software to direct cutting tools along multiple axes. These automated systems shape raw materials into exact parts for industries that require tight tolerances.

The Role of the Computer and Software

CNC milling control depends on an integrated computer and computer-aided manufacturing (CAM) software. Operators upload a digital part design, usually as a CAD (computer-aided design) file. CAM software converts the CAD data into a set of G-code instructions. The CNC computer transmits these codes to the motion control system, guiding spindle speeds, tool paths, feed rates, and axis movements with micron-level precision. At Yijin Hardware in Homestead, FL, technicians use advanced CNC software to ensure consistent accuracy for aerospace and medical part production.

Step-by-Step Milling Process

A CNC milling machine process starts with securing a workpiece on the machine’s worktable. The machine reads the program code, activating the spindle and moving the selected cutting tool into position. Step one positions the tool above the stock. Step two initiates the toolpath sequence along the programmed X, Y, and Z axes. The tool follows assigned movements, removing material in precise increments to create features like slots or pockets. Operators monitor status through the CNC interface, which delivers real-time feedback to avoid errors. Companies like Yijin Hardware apply this sequence to produce components with repeatable quality for sectors like automotive and energy.

Tool Changes and Automation

CNC milling incorporates automatic tool changing systems to switch tools based on programmed instructions. The automated carousel or tool magazine holds an assortment of end mills, drills, or taps for complex machining cycles. When the process calls for a different operation, the system retracts the current tool and installs the required one, often in under ten seconds. Automated tool changes boost productivity, decrease setup times, and help maintain tight production schedules. At Yijin Hardware, these automated features support high-mix, low-volume runs in precision manufacturing for clients across multiple industries.

Advantages of CNC Milling Machines

- Precision and Repeatability

CNC milling machines achieve tolerances as tight as ±0.001 in, enabling consistent part production for high-requirement sectors like aerospace and medical device manufacturing. Integrated feedback systems maintain accuracy throughout production cycles.

- Increased Productivity and Efficiency

Automated operation allows CNC mills to run continuously with minimal supervision, supporting 24/7 operation in manufacturing environments. Yijin Hardware in Homestead, FL utilizes advanced CNC systems for high-throughput production, reducing manual intervention.

- Complex Geometry Capability

Multi-axis movement enables CNC milling machines to produce intricate features, such as 3D contours and angled holes. These capabilities allow for sophisticated parts in custom hardware and prototyping services.

- Reduced Human Error

Pre-programmed instructions and automated tool changes limit opportunities for manual mistakes. Yijin Hardware implements real-time monitoring for each batch, minimizing rework rates.

- Material Versatility

CNC mills process metals, plastics, and composites, such as aluminum, steel, or PEEK. This versatility supports industries like automotive and energy manufacturing, which require parts from different material classes.

- Cost-Effectiveness in Medium to Large Volumes

Once programming is complete, CNC milling minimizes per-unit labor costs through automated tool paths. Companies see significant savings for production runs over 100 units.

- Rapid Turnaround and Prototyping

Direct CAD-to-machine workflow enables quick setup changes and fast revisions. Yijin Hardware offers expedited CNC milling for prototype and production needs, improving speed-to-market.

- Enhanced Safety

Fully enclosed work zones reduce direct operator exposure to moving components, limiting workplace accidents during automated cycles.

| Advantage | Description | Industry Example |

|---|---|---|

| Precision & Repeatability | Tolerances to ±0.001 in, continuous accuracy | Aerospace, Medical Devices |

| Productivity | 24/7 operation, low supervision | Automotive |

| Complexity | Multi-axis cutting for advanced geometry | Custom Hardware |

| Error Reduction | Automated tool paths, real-time monitoring | Energy |

| Material Versatility | Processes metals, plastics, composites | All Industries |

| Cost-Effectiveness | Low per-part cost for 100+ units | Automotive |

| Turnaround | CAD-to-part in days for prototypes | Product Development |

| Safety | Enclosed work areas, fewer accidents | Manufacturing Facilities |

Common Applications of CNC Milling Machines

CNC milling machines operate in sectors that need high precision and repeatability. Aerospace manufacturers use CNC milling to produce turbine blades, brackets, and landing gear parts with tolerances up to ±0.001 inches. Automotive suppliers rely on CNC milling for engine blocks, transmission housings, and prototype components, ensuring consistency for medium to high-volume runs. Medical device companies utilize CNC milling for implantable devices, surgical instruments, and diagnostic equipment, meeting strict FDA standards for accuracy.

Electronics companies depend on CNC milling to create heat sinks, enclosures, and circuit board housings from aluminum and plastics. Energy firms apply CNC milling to build valve components, pump housings, and custom fasteners that meet operational and safety requirements. At Yijin Hardware in Homestead, FL, CNC milling supports clients needing custom hardware, sheet metal fabrication, and precision machined parts for all these sectors. Yijin Hardware offers multi-axis machining, quick-turn prototyping, and certified quality control. Gavin Yi, CEO, ensures every project is delivered with reliable support and clear communication throughout the process.

About Yijin Hardware

Yijin Hardware offers a range of precision manufacturing services, including CNC machining, sheet metal fabrication, and custom fasteners. They also provide additional solutions such as die casting, injection molding, and 3D printing to support various industries like automotive, aerospace, medical, and energy. Whether it’s a complex machined component or a custom manufacturing solution, they are equipped to deliver high-quality results for diverse industrial applications.

Contact:

Gavin Yi, CEO

Phone: +1 626 263 5841

Email: yijing@yijinsolution.com

Website: yijinsolution.com

Location:

760 NW 10th Ave, Homestead, FL 33030

Frequently Asked Questions

What is a CNC milling machine?

A CNC milling machine is a computer-controlled tool that precisely removes material from a workpiece to create complex, high-accuracy parts. It follows programmed instructions to guide cutting tools along multiple axes.

What materials can CNC milling machines work with?

CNC milling machines can process a wide range of materials, including metals like aluminum and steel, as well as plastics and composites, making them suitable for diverse industries.

How does CNC milling differ from traditional milling?

CNC milling automates the cutting process with computer guidance, allowing for greater precision, repeatability, and complexity compared to manually operated traditional milling machines.

What industries benefit most from CNC milling machines?

Industries such as aerospace, automotive, medical, electronics, and energy use CNC milling machines for parts that require high accuracy, consistency, and tight tolerances.

What are the main advantages of CNC milling?

Main advantages include exceptional precision, repeatability, multi-axis capabilities, material versatility, higher productivity, reduced human error, improved safety, and cost-effectiveness for medium to large production volumes.

How accurate are CNC milling machines?

Modern CNC milling machines can achieve tolerances as tight as ±0.001 inches, which is crucial for sectors such as aerospace and medical device manufacturing.

What is G-code and its role in CNC milling?

G-code is a programming language used to instruct CNC milling machines on movement, tool actions, and speed. It converts digital CAD designs into actionable steps for precise machining.

What kinds of parts can be made using CNC milling?

CNC milling produces a variety of parts, including engine blocks, turbine blades, implants, surgical instruments, circuit board housings, and custom fasteners for various industries.

How does the automatic tool changer benefit production?

Automatic tool changers allow CNC machines to quickly switch between tools during complex tasks, boosting productivity and supporting high-mix, low-volume production runs.

Why choose Yijin Hardware for CNC milling services?

Yijin Hardware offers advanced CNC milling with multiple axes, adjustable spindle speeds, and strict quality control, ensuring precise, repeatable parts and reliable service for demanding industries.